Understanding the 4 Material Options for Capacitive Tactile Sensors

Introduction

Capacitive tactile sensors are revolutionising the way we interact with objects and surfaces. Just as visually impaired individuals can create mental images through touch, capacitive tactile sensors enable devices to “see” and interpret the world through contact mechanics. Whether it’s for wearable electronics, industrial sensors, or robotics, choosing the right tactile sensor material is critical for optimal performance. Each material offers unique properties, advantages, and limitations, making the choice highly application-specific.

This article explores four material options for capacitive tactile sensors - conductive cloth, conductive Lycra, flex circuit, and hybrid constructions - highlighting their unique characteristics and best applications. Additionally, we’ll answer common questions about how tactile sensors are made, and the advanced sensor materials used in their construction.

How Are Tactile Sensors Made?

Tactile sensors are constructed by layering advanced sensor materials in configurations that measure changes in capacitance. The key steps include:

Material Selection: Identifying suitable materials like conductive cloth, conductive Lycra, or flex circuit based on the application.

Layering: Building multi-layered structures with electrodes and dielectric layers for precision measurements.

Patterning: Using methods such as etching or laser cutting to create functional patterns.

Encapsulation: Protecting sensors with coatings to enhance durability for applications in wearable devices or industrial environments.

These processes rely on engineering advancements in materials science and precision manufacturing. For further insights, refer to Electrical Volt’s guide on tactile sensors.

What Materials Are Used for Tactile Sensors?

Tactile sensors use a variety of functional materials, each tailored for specific requirements. Key factors such as flexibility, stretchability, and durability dictate the choice of material for applications like biomedical devices, environmental monitoring, and wearable electronics.

The primary materials include:

Conductive Cloth: Flexible and lightweight, ideal for wearable applications and soft robotics.

Conductive Lycra: Metalized stretchable material suitable for deformable surfaces and dynamic sensing in smart textiles.

Flex circuits: Etched copper on durable Kapton material designed for high-temperature and industrial uses.

Hybrid Materials: Combining properties of cloth and Kapton for balanced performance in consumer and medical technologies.

For detailed discussions on the benefits of conductive fabrics, visit Textile Blog’s overview.

Conductive Cloth: Conformable and Flexible

Material Overview:

Conductive cloth, made from two types of metal-plated fibres, offers exceptional versatility. The electrode layer typically uses woven nickel- or copper-plated yarn, while shielding layers are composed of knitted silver-plated fabrics to reduce interference. This combination ensures high sensitivity and accuracy. Encapsulation with soft polymers adds waterproofing and enhances durability. Lightweight and moldable, conductive cloth adapts seamlessly to curved or multi-surfaced geometries, making it ideal for portable and wearable devices.

Advantages:

High flexibility, conforming to complex shapes and curved surfaces.

Lightweight, ensuring comfort and ease of integration.

Operates effectively in moderate temperature ranges (-20°C to 100°C).

Best Applications:

Medical Devices: Enables real-time health monitoring by detecting changes in skin pressure or subtle biometric signals, crucial for prosthetics and wearable diagnostics.

Wearable Electronics: Used in fitness trackers and flexible robotics, enhancing user interaction and rehabilitation support.

Robotics: Enables sensitive grippers for handling delicate items such as fruits, glassware, or precision instruments.

Limitations:

Moderate durability in harsh or high-pressure environments.

Restricted pressure range (1 psi to 80 psi), limiting industrial use cases.

2. Conductive Lycra: Stretchable and Dynamic

Material Overview:

Conductive Lycra is engineered with conductive silver-metallised coating, delivers stretchability and dynamic responsiveness. It accommodates up to 10% deformation without baseline drift, making it indispensable for applications involving motion or flexibility. Its ability to cover extensive surface areas in 1D and 2D layouts ensures adaptability for diverse designs, from smart textiles to adaptive surfaces.

Advantages:

Allows for repeated stretching and flexing, ideal for dynamic sensing environments.

Supports large-area coverage, ensuring versatility across smart furniture and garments.

Integrates seamlessly into irregular or curved objects such as a human head, enabling ergonomic designs.

Best Applications:

Smart Textiles: Ideal for diagnostics, such as monitoring heart rate or posture in athletes and healthcare settings.

Furniture and Bedding: Embedded in ergonomic cushions or mattresses for pressure monitoring and comfort enhancement.

Rehabilitation Exoskeletons: Flexible sensors integrated into robotic suits to aid mobility and track therapeutic progress.

Limitations:

Constrained to low-pressure measurements (5 psi to 50 psi).

Limited temperature tolerance (-20°C to 50°C), which restricts outdoor or extreme applications.

3. Flex Circuit: Industrial and Robust

Material Overview:

Kapton, a polyimide film, is foundational for flexible circuit industries and a benchmark for high durability. Its rigidity and stability under extreme conditions make it indispensable for heavy-duty applications. Withstanding temperatures up to 200°C and pressures up to 2000 psi, it excels in precision-demanding environments.

Advantages:

Extremely thin (0.3 mm), maintaining durability in high-stress conditions.

Operates under extreme temperatures and pressures, ensuring performance reliability.

Versatile in applications requiring stability and precision.

Best Applications:

Industrial Sensors: Optimised for machinery that requires accurate pressure measurements, aiding predictive maintenance and operational efficiency.

Automotive Systems: Integral for monitoring engine components, braking systems, and safety-critical technologies.

Limitations:

Reduced flexibility compared to conductive Lycra or conductive cloth.

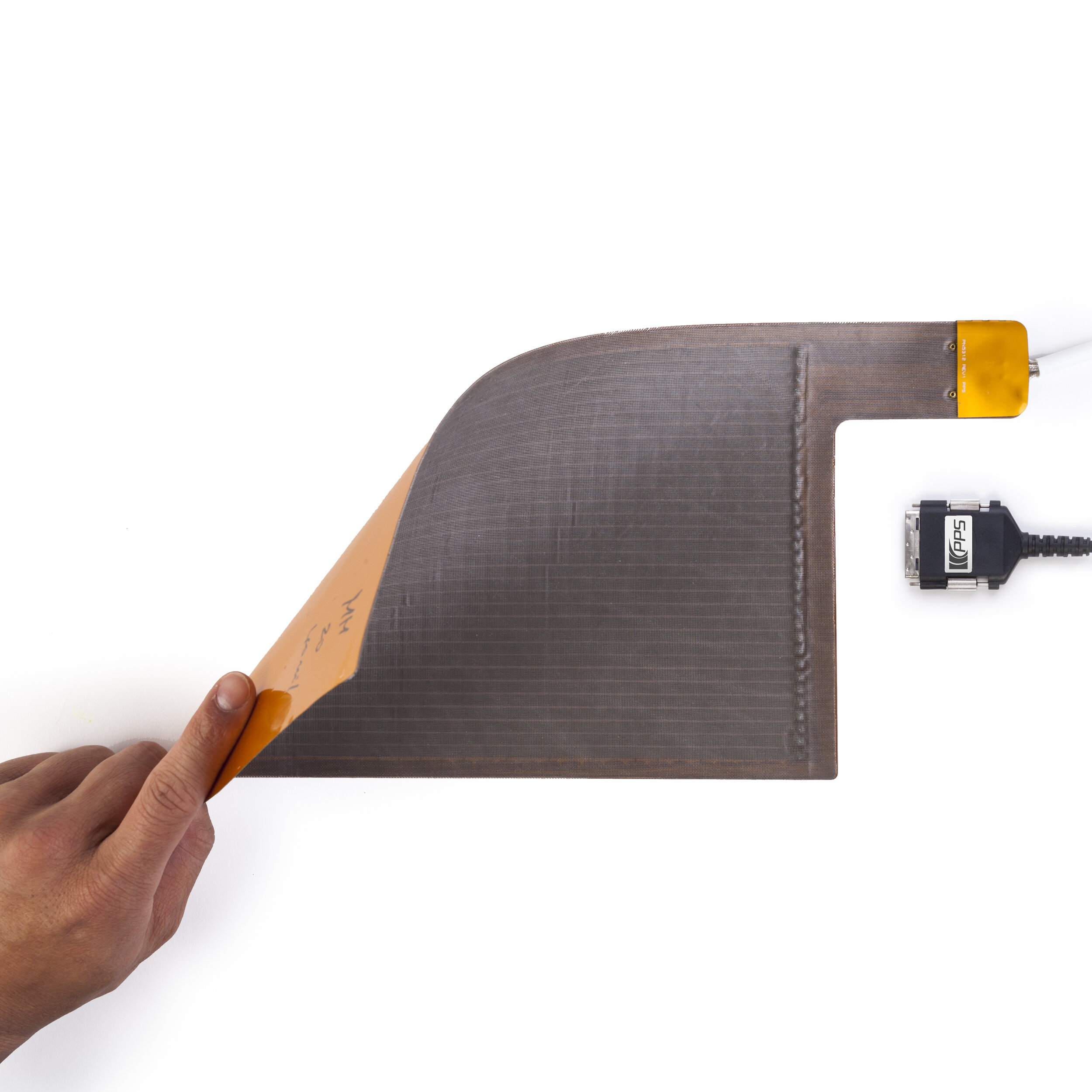

4. Hybrid Materials: Versatile and Balanced

Material Overview:

Hybrid sensors merge the strengths of conductive cloth and Kapton, offering a balanced solution for diverse applications. This combination supports flexibility and durability, making them adaptable to both dynamic environments and demanding industrial use. Encapsulation methods allow integration into intricate devices without compromising performance.

Advantages:

Combines flexibility with structural integrity, catering to varied use cases.

Offers customisable designs to address specific functional needs.

Performs well in both wearable and industrial settings, bridging gaps between consumer and technical applications.

Best Applications:

Medical Devices: Aids in diagnostic tools and wearable health trackers that monitor chronic conditions or recovery progress.

Robotics: Powers adaptive grippers and precision mechanisms, enabling interaction with fragile or irregular objects.

Limitations:

Complex manufacturing processes due to material integration.

Moderate limitations in extreme conditions, such as very high pressures or temperatures.

Choosing the Right Material for Your Application

The material selection for capacitive tactile sensors depends on application-specific requirements:

Need flexible interaction with curved surfaces? Conductive Cloth is optimal.

For stretchable, soft materials in wearables, use Conductive Lycra.

Require durability in harsh environments? Kapton based flex circuit is the answer.

Seeking balanced performance? Opt for Hybrid Materials.

These advanced materials enable breakthroughs in fields like human health, environmental monitoring, and industrial automation, illustrating the potential of materials science to innovate sensor technologies. For recent developments in stretchable sensors, check out Wyss Institute’s research.

Final Thoughts

Capacitive tactile sensors, enabled by advanced materials and manufacturing techniques, are transforming industries ranging from wearable electronics to industrial automation. By understanding the properties of these functional materials, engineers can design devices that provide sensitive, reliable measurements in a variety of applications.

Stay tuned for more updates on integrating tactile sensors into cutting-edge systems, where science meets engineering to enhance safety, human interaction, and innovation.